Guide frame

The side wall of the gas drum should be just as high as the wall above the support ledge.

The floating-drum must not touch the outer walls. It must not tilt, otherwise the coating will be

damaged or it will get stuck. For this reason, a floating-drum always requires a guide. This

guide frame must be designed in a way that allows the gas drum to be removed for repair.

The drum can only be removed if air can flow into it, either by opening the gas outlet or by

emptying the water jacket.

The floating gas drum can be replaced by a balloon above the digester. This reduces

construction costs but in practice problems always arise with the attachment of the balloon to

the digester and with the high susceptibility to physical damage.

Types of floating-drum plants

There are different types of floating-drum plants (see drawings under Construction):

• KVIC model with a cylindrical digester, the oldest and most widespread floating drum

biogas plant from India.

• Pragati model with a hemisphere digester

• Ganesh model made of angular steel and plastic foil

• floating-drum plant made of pre-fabricated reinforced concrete compound units

• floating-drum plant made of fibre-glass reinforced polyester

• BORDA model: The BORDA-plant combines the static advantages of hemispherical

digester with the process-stability of the floating-drum and the longer life span of a

water jacket plant.

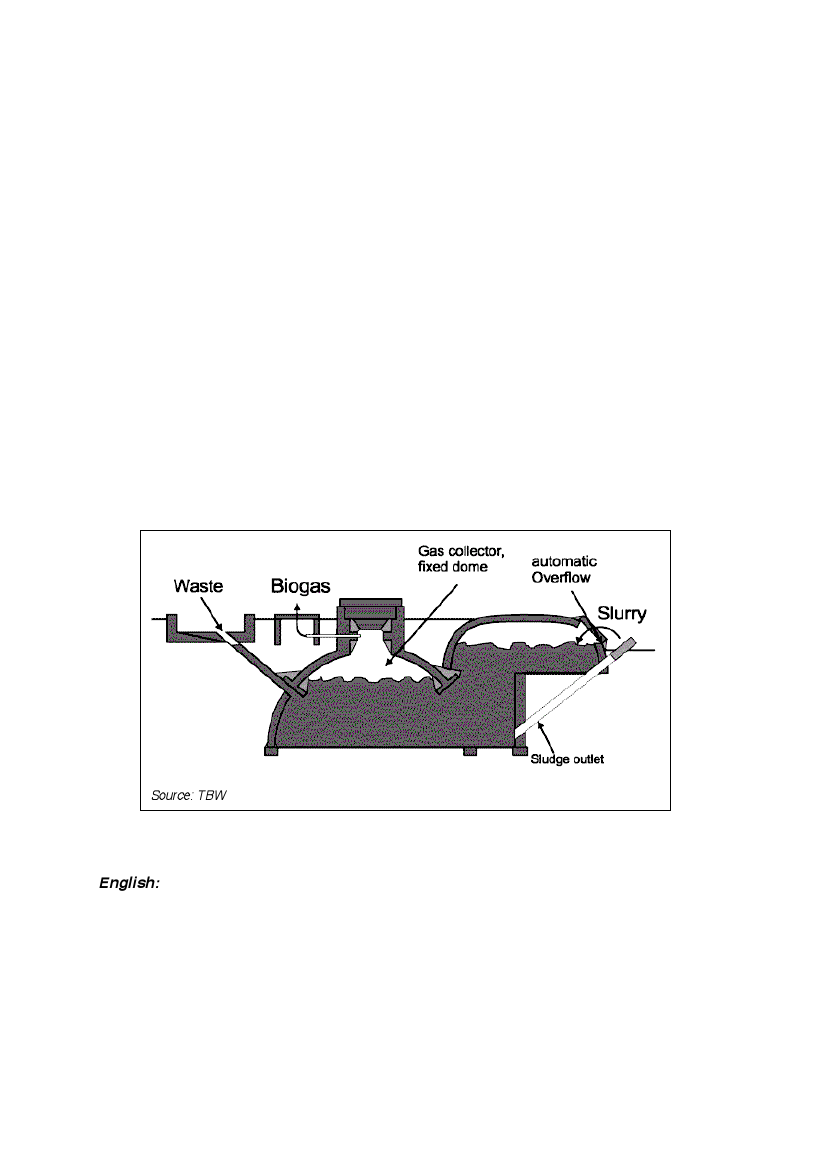

Figure 10: Fixed dome plant CAMARTEC design

Source: TBW

Further reading:

English:

• Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of

Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion,

London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3

• van Buren, A.; Crook, M.: A Chinese Biogas Manual - Popularising Technology in the

Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth

impression 1985, 135 P. ISBN: 0903031655

• Fulford, D.: Fixed Concrete Dome Design. Biogas - Challenges and Experience from

Nepal. Vol I. United Mission to Nepal, 1985, pp. 3.1-3.10.

13